Electric Motor Manufacturers

Specialized in electric motors for industrial machines, gearboxes, water pump

What is an Electric Motor?

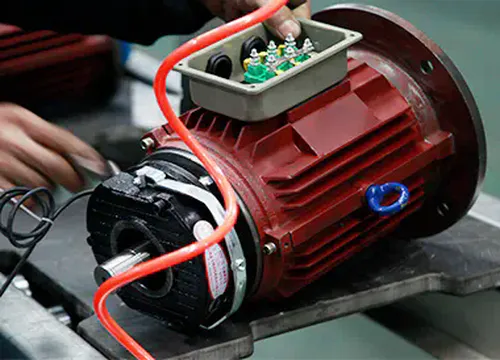

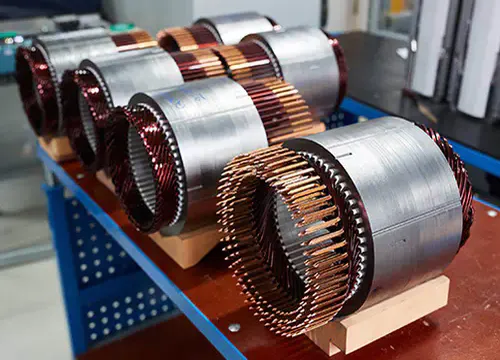

Stator (static part)

Function: Part of the motor’s magnetic circuit on which the stator windings are placed.

Stator winding

Function: It is the circuit part of the motor, which is connected to a three-phase alternating current to generate a rotating magnetic field.

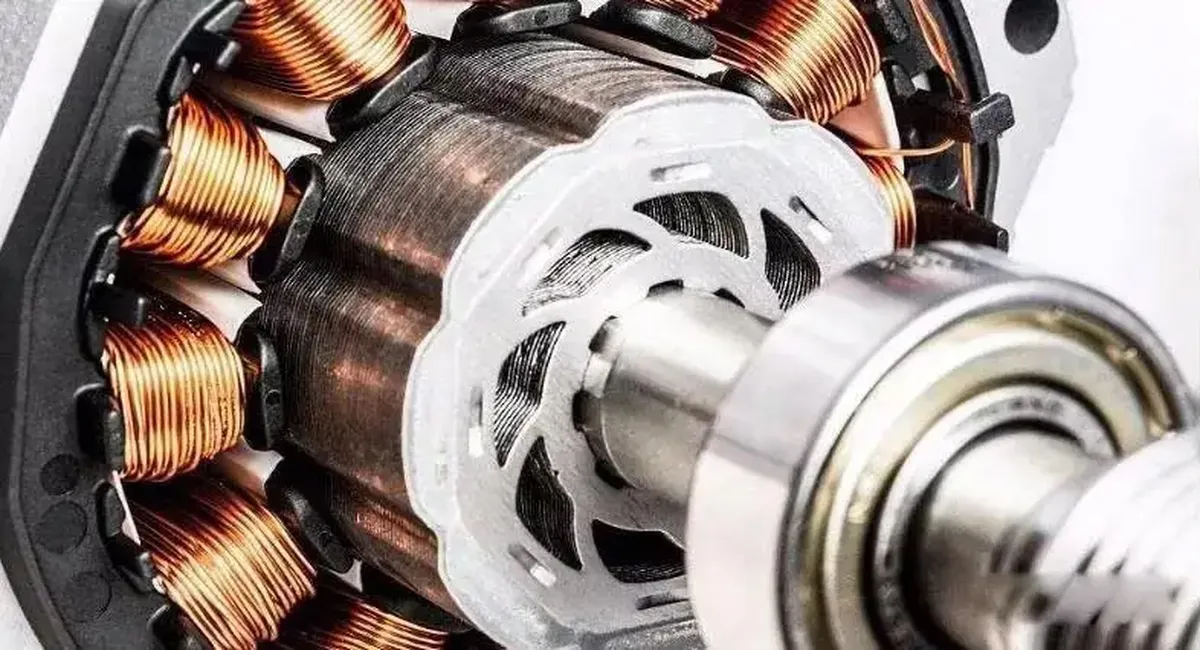

Rotor (rotating part)

unction: As part of the motor’s magnetic circuit and to place the rotor winding in the core slot.

Rotor winding

Function: Cutting the stator’s rotating magnetic field generates induced electromotive force and current and forms electromagnetic torque to rotate the motor.

Machine base

Featured Electric Motors for Sale

The following list is only a partial display of electric motor products, and more electric motor products are in succession on the shelves. Please contact us by email if you need to buy an electric motor. Email: [email protected]

YC Series Heavy Duty Single Phase Induction Electric Motor

YBX3 Series Flameproof Three-phase Induction Electric Motor

Y2 Series Three Phase Squirrel Cage Induction Electric Motor

Y2 series three-phase induction motors are designed especially for the European market, whose terminal box is located on the top of the motor. The motor has a very compact structure and attractive appearance, and the sizes and mounting dimensions all conform with IEC standards. The motor has some good features, such as high efficiency and energy-saving. High starting torque and easy maintenance etc.

MY Series Aluminum Housing Single Phase Capacitor-Run Induction Electric Motor

MY series is a single-phase, capacitor-run, asynchronous, and ac induction motor. It is an enclosed fan-cooled type. MY series motors have the following features: good performance, safe and reliable operation, nice appearance, convenient maintenance, low noise, slight vibration, low-temperature rise, high overload capacity, lightweight, and simple construction.

YVF3 Series Variable Frequency Three Phase AC Asynchronous Induction Electric Motor

YVF3 series variable frequency 3-phase induction motor is based on the YE3 engine. YVF3 series motor adopts a high-strength cast iron structure, which has the characteristics of high reliability, wide speed regulation range, and high precision. It is equipped with an independent cooling fan to ensure the motor has an excellent cooling effect at different speeds.

YE2 Series High-Efficiency Three-Phase Induction Electric Motor

The YE2 Three-phase electric motor is a fully closed, self-fan cold mouse cage three-phase asynchronous motor manufactured with new materials, new techniques, and optimized design. Have high efficiency, high starting torque, low noise, more reasonable structure, and cooling conditions mature. It can be used to drive various available mechanical equipment.

All Categories

- Stainless Steel Motors

- NEMA Stainless Steel Stepper Motor With Double Capacitor

- IEC B5 Flange Mounted Stainless Steel Motor -TENV

- IEC Stainless Steel Motor B3 Foot Mounted TEFC

- IEC Stainless Steel Motor B3 Foot Mounted-TENV

- B14 Face Mounted Stainless Steel Motor TEFC

- B5 Flange Mounted Stainless Steel Motor-TEFC For Food machinery

- Spindle Motors

- Pneumatic Unclamp Cylinder

- Electrical Spindle for Special Usage

- Spindle Motor Used for Lathe JSZD150T JSZD110J

- Spindle Motor Used for Lathe JSZD280

- Spindle Motor Used for CNC Spindle JSZD320

- Spindle Motor Used for Grinding Spindle

- Spindle Motor Used for Engraving and Milling

- Spindle Motor Used for CNC Spindle JSZD150C

- Spindle Motor Used for CNC Spindle JSZD170C

Different Application of Electric Motor

“Due to high resistance and commendable torque rate, lifting industries are the main application of three-phase motors. Slip Ring motors can carry a high load without causing overheating. Cranes, accelerators, elevators, hoists, and conveyors are the common 3 phase motor uses in the lifting industry. ”

“Slip ring induction motors are also widely used in the high-volume compressors and crushers in petroleum refineries and the gas extraction industry. These motors have high load capacity; therefore, the chemical industry is the major application of 3-phase induction motors.”

“Squirrel cage electric motors are used in the lathe machines for cutting, tapering, and parting purposes. For example, grinders, lathes, millers, and machine tools. These motors are efficient and long-lasting; therefore, perfect choice for low-grade commercial purposes.”

Other Type Electric Motor

YD Series Three Phase Asynchronous Electric Motor

- Rated voltage: 380V or any voltage between 220-760V

- Frequency: 50/60HZ

- Shell: cast iron body, aluminum body

- Pole: 2, 4, 6, 8, 10, 12

- Protection degree: IP55, IP54

- Mounting arrangement: B3/B5/B14/B35/B34 or other

- Efficiency Standard: EFF2, EFF1

YEJ2 Series Three-Phase Asynchronous Motor

- Mounting arrangement: B3/B5/B35/B34 or other;

- Pole: 2/4/6 poles;

- Rated Voltage and Frequency: 380V 50HZ

- Duty/Rating: S1 (Continuous);

- Types of braking: Braking when power off

- Cooling method: IC411 (SELF-FAN cooling);

- Insulation class: 155(F);

MS Series Three-Phase Asynchronous Motor

- Rated voltage: 380V or any voltage between 220-760V

- Frequency: 50Hz, 60Hz;

- Protection class: IP54/IP55

- Mounting types: IMB3, IMB5, IMB35, IMB34, IMB14

- Materials: Cast iron, aluminum

- Poles: 2, 4, 6, 8

- Cooling method: IC411

Learn About Electric Motor Related Information

How do Electric Motors work?

The basic idea behind how electric motors work is simple: the rotor spins inside a stator that is connected to an electrical supply. The rotor rotates when an electromagnetic field produces attractive and replusive forces. When the rotor turns faster than the magnetic field, it recharges the battery and acts as an alternator.

The rotor and electromagnets in an electric motor are connected by coils of wire. When power is applied to a coil, the coils of wire turn into an electromagnet. This electromagnet attracts the opposite pole of the magnet. The current is then switched from one pole to the other by changing the polarity of the commutator.

The physical principle of electric motors is the same for both DC and alternating current (AC) motors. The basic premise is that a magnetic field is created every time an electric charge moves. In a simple DC motor, a magnetic field is generated on the stator’s two components.

Differences and connections between DC motors and AC motors?

Taking the motor as an example, if the motor wants to work, it must rely on the electromagnetic force induced by the rotor winding to drive the rotor to rotate. Therefore, in order to ensure the stable and continuous rotation of the motor, the induced electromagnetic force in the rotor winding must keep the same direction. For DC For the motor, the direction of the stator magnetic field does not change, so if the current in the rotor is not commutated, the direction of the electromagnetic force received by the rotor during the rotation will change, and the continuous rotation of the rotor cannot be guaranteed. That is, as long as the direction of the electromagnetic force in the rotor windings is consistent, the rotor can continue to rotate.

The working principle of DC and AC motors is the law of electromagnetic induction, but there are also differences between the two, which can be understood through the different starting methods of the two. The rotation of the DC motor rotor (armature winding movement or force) is because the energized armature winding is subjected to electromagnetic force in the magnetic field, so the premise is that there is current in the armature, so the DC motor needs armature current to start; When the motor starts, as long as alternating current is applied to the stator, a rotating magnetic field will be generated.

Since this magnetic field is moving, the rotor winding will induce an electromotive force. As long as the rotor winding can form a closed loop, a current will be generated, and an electromagnetic field will be induced. The force drags the rotor to rotate, so the premise of the rotor movement of the AC motor is that the magnetic field is rotating, which is the difference between the two in the initial state of movement.

Why Some Motors Use Insulated Bearings?

Flashovers caused by induced currents on the spindle and bearings can lead to defects such as corrosion of the bearing surfaces, shrinkage cavities on the metal surfaces, and grooves in the bearing rolling tracks. One of the most important features of insulated bearings is that there is a very thin (um level) coating on the surface, which is responsible for electrical insulation and can resist electrical flashovers generated at voltages over 500V. Thicker coatings can resist 1000V. High voltage discharge.

First of all, for safety, at high frequency, the rotor induced current will be very large, preventing the motor shaft current. If the electrical insulating bearing is not used, the current will flow through the bearing to form a circulating current, and the bearing will be easily damaged by heat or electric water splash. The most significant feature of the electrical corrosion of the bearing by the high-frequency shaft current in the variable frequency speed regulating motor is the dense groove stripes produced on the inner and outer rings and balls of the motor bearing. Therefore, the motor must be electrically insulated at one end.